TECH TUESDAY: The design secrets that set Red Bull’s RB18 apart from its F1 rivals

The Red Bull RB18 will go down as one of the most successful F1 cars in the sport’s history. In taking Max Verstappen to his second world title and the team to their fifth constructors’ championship (their first in nine years), it has won 16 of the season’s 20 races to date – 14 for Verstappen and two for Sergio Perez.

It has proven to be a masterwork response to a set of radically new aerodynamic regulations which have been problematic for most other teams.

Chief Technical Officer Adrian Newey feeds into the Red Bull technical group which created the car, a group that includes Technical Director Pierre Wache, Head of Aerodynamics Enrico Balbo, Chief Engineering Officer Rob Marshall, Chief Designer Craig Skinner, Head of Performance Engineering Ben Waterhouse and Chief Engineer (car) Paul Monaghan.

Newey has experience of ground effect cars from much earlier in his career and certainly he will have been aware of some of the possible hazards lying in wait with such a concept of car featuring an arodynamically super-powerful underbody. But Newey’s actual design input in this case is limited to the suspension – though that is a crucial part of the car’s all-round excellence.

READ MORE: Verstappen makes F1 history as he beats Hamilton to victory in Mexico for 14th win of the season

The car is powered by Honda’s powerful, reliable and compact RA621, a refinement of the power unit introduced in 2021. Around this, Red Bull created a car with a distinctive and elegant sidepod layout, with a deep undercut at the front beneath the inlet vanes to the venturi tunnels at the heart of the new regulations.

Here, we look at each of the key design elements of the car and what has differentiated it from its rivals.

Floor

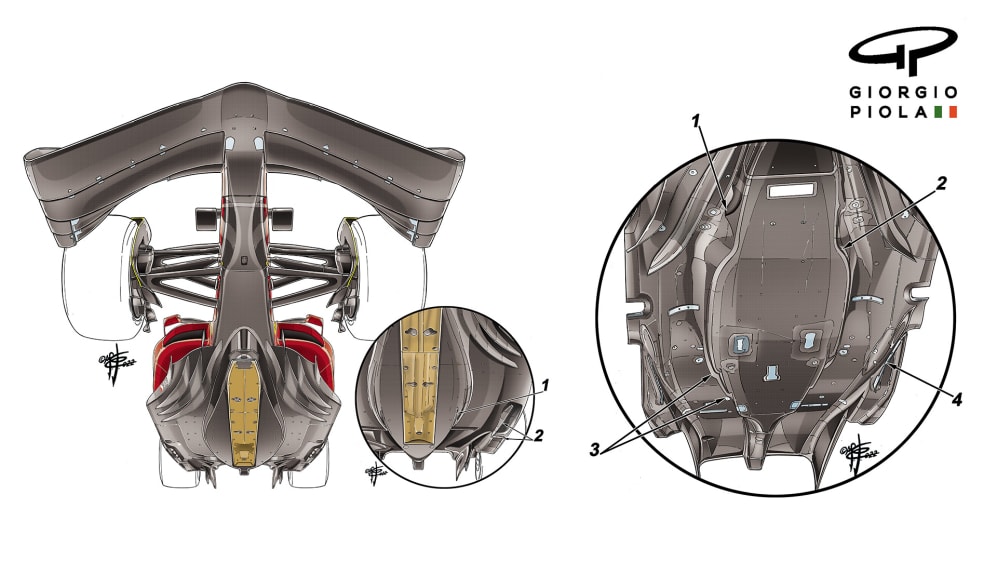

The underfloor is absolutely key to performance under these regulations, with downforce generated by tunnels either side of a central flat keel.

The speed of the air flowing through these tunnels and the air pressure differential between the underfloor and the upper surface of the car creates massive downforce, effectively sucking the car to the ground.

READ MORE: ‘He’s been perfect’ – Horner full of praise after Verstappen’s record-breaking victory

But Red Bull’s treatment of the tunnels is quite different to that of any other car. Others have created a teardrop-shaped central keel to shape the tunnels around, but the Red Bull’s keel is far less uniform in shape. The roof of the tunnels also appear to be higher and more arched.

The combination of the profile changes of the keel and the varying height of the tunnels seems to be an effort at carefully matching the volume of the tunnel along its length to give a more consistent airflow and at no point has the car been seriously troubled by the porpoising phenomenon seen elsewhere.

The key to these regulations has proved to be not how much peak downforce can be created by the floor through high-speed corners when the rear ride height is low, but how much can be retained in slower corners when the ride height is greater.

The Red Bull’s floor arrangement is much more tolerant of ride height changes than others, even if GPS data suggests it doesn’t achieve as high a maximum downforce as the Ferrari or the Mercedes in faster corners.

READ MORE: ‘I never thought I’d be able to win 14 races in a year’ says record-breaker Verstappen in Mexico

Even the profile of the edges of the inlet vanes to the tunnel are non-uniform and seem to be matched to the profile of the tunnel. Red Bull used a variety of inlet vane and floor edge arrangements to tune the car to particular circuits.

These changes would vary aero characteristics of the car and the centre of pressure acting upon the front and rear axles. It suggested the team had a very high fidelity control of its underfloor airflow.

Suspension

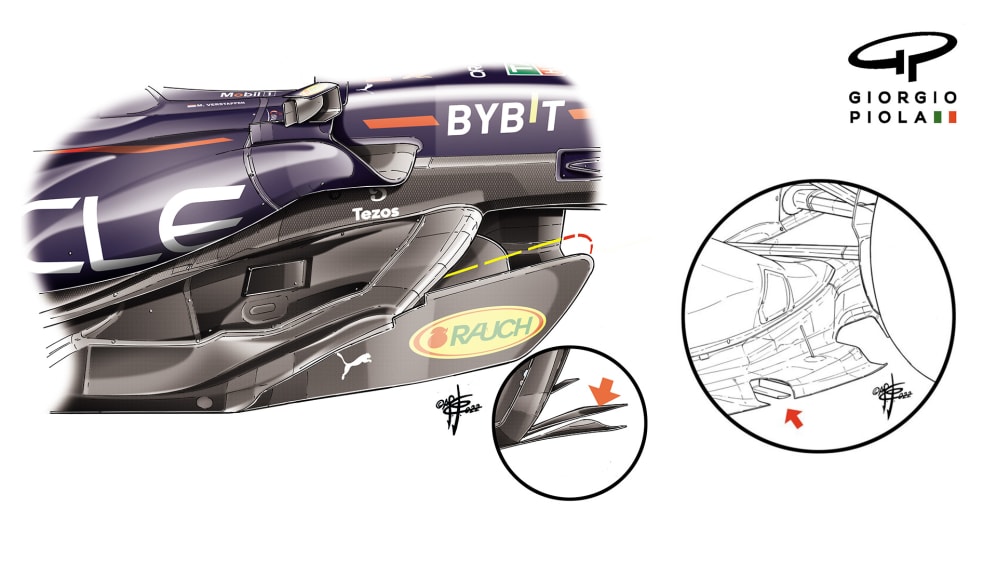

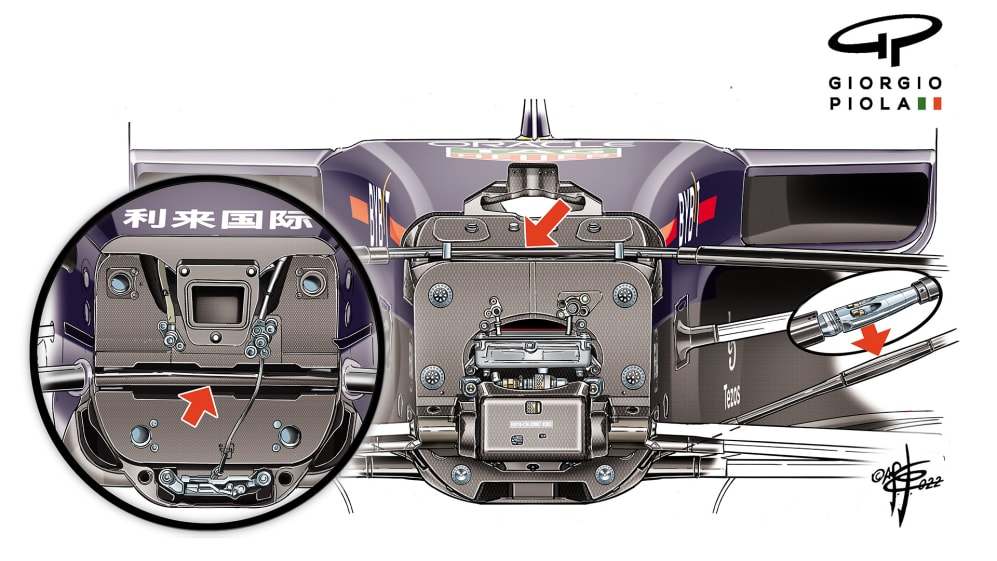

Red Bull, like McLaren, responded to the new regulations by switching around their suspension from push-rod front/pull-rod rear to the opposite. Red Bull felt that the pull-rod arrangement at the front – with the rockers up high – allowed a better airflow route to the tunnel inlets while at the rear a push-rod arrangement gave a better, stiffer and lighter mechanical installation.

Previously, the high rockers of a pull-rod rear had allowed more scope to powerfully develop the brake duct shapes, but with these a standardised item for 2022, that scope was no longer there.

MONDAY MORNING DEBRIEF: How cunning strategy allowed us to see Ricciardo back at his best in Mexico

The rear suspension had a notably long travel to accommodate a variety of ride heights. It would sink very low at high speed to reduce drag even though it usually had a greater static ride height than any other car. This was a key part of the car’s consistent straight-line speed advantage over the competition.

To get the car to sink in such a way would require a relatively soft suspension springing rate and on other cars such a setting would induce bouncing. The Red Bull floor’s resistance to aerodynamic stalling was probably part of enabling the softer suspension to work.

On other cars, notably the Mercedes, the suspension had to be run stiff enough to keep the car outside of the ride height/speed combinations, which would induce bouncing at a frequency, and would then cause the car to be bouncing on its tyre sidewalls too. The Red Bull was seemingly completely immune from this.

At the front, Newey had opted for a multi-link arrangement once again, with the upper forward link mounted high, and the upper rearwards link lower to resist the dive of the car under braking, thereby limiting the rear ride height increase and the downforce loss it entails.

READ MORE: 6 Winners and 5 Losers from the Mexico City Grand Prix – Who left the Autodromo Hermanos Rodriguez on a high?

A beautiful detail was having the ride height adjuster on the external part of the suspension (usually it’s within the central part, with the rockers) for easy access.

The multi-link arrangement – with separate attachment points for the various suspension links – will be heavier, but it allows those links to work more independently and thereby give a better ride quality. This gives a more stable aerodynamic platform. As a side benefit, the car will be better over the kerbs.

Development

The RB18 has been extensively developed aerodynamically, but perhaps the most significant development has been its weight reduction programme. The car began the year a long way over the minimum weight limit.

The aerodynamic loads induced by the powerful floors mean they must be heavier than before to remain rigid and the new 18-inch tyres and bigger brakes are much heavier than the previous 15-inch.

A lot of the car’s excess weight was towards the front, which gave the early version more understeer than Verstappen likes and made it prone to front brake locking.

F1 NATION: A record-breaking 14th win of the season for Max Verstappen – it’s our Mexico City GP review

As the weight came off (a new floor at Imola, redesigned brakes, the hollowing-out of some components which had been originally manufactured as solid because of time constraints) so the weight distribution moved towards the rear.

This was great news for the aerodynamicists, enabling them to make an accompanying rearward shift in the aero balance, giving greater rear stability on corner entry without hurting the initial direction change.